Our Client

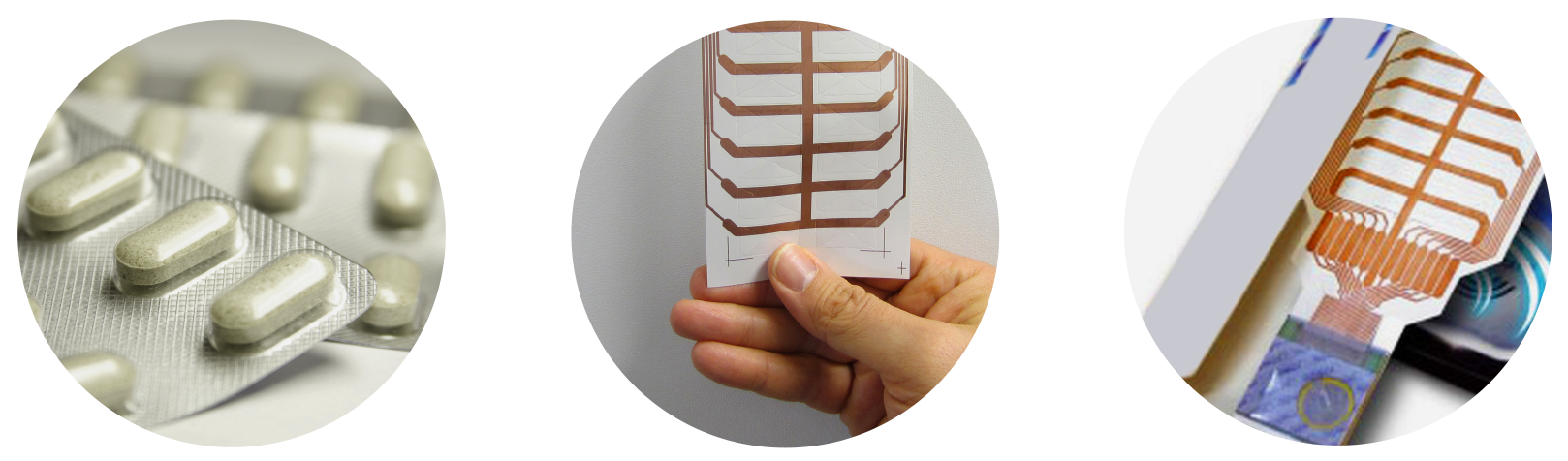

A global corporation conducting R&D in pharmaceutical logistics and supply chain compliance technologies. Their purpose was to develop a system of monitoring and reporting if or when a research subject took their medication. Working in conjunction with pharmaceutical companies, the company developed special packaging to be used as part of medication trial runs. The system consisted of:

- A hidden RFID transmitter embedded within a medication blister pack

- When the pill is removed from the package, the foil seal is broken causing the RFID transmitter to send a signal within 4 seconds

- This provides real-time data of when medication is removed and assumed to be consumed

The Challenge

- The RFID transmitter could not come into contact with the medication in the pill dispenser – no incidental food contact

- The transmitter’s trigger had to be activated when the aluminum foil seal was broken

- The fragile neck of the transmitter had to be reinforced without adding bulk to the package

- The product required multiple stages of complex die cutting and precisely placed adhesive

The Solution

- Developing a technique of precision die cutting, ensuring that when the pill was pushed out of the package, it would trigger the transmitter EVERY time. This required a precision die cutting specification of 0.005 inches

- The reinforced neck of the transmitter required precision die cutting (0.004 inches) and very tight tolerance component placement

The Outcome

- The drug trial has been so successful that the company is expanding the product’s use from drug research to commercial applications

- The layering of the hidden RFID transmitter has been very successful, and constant minute improvements continue to be made