Biochip and Micro-Fabrication

Our Client A recognized world leader in biochips and micro-fabrication of solid-state diagnostic devices. Their products comprise a range of acute-care

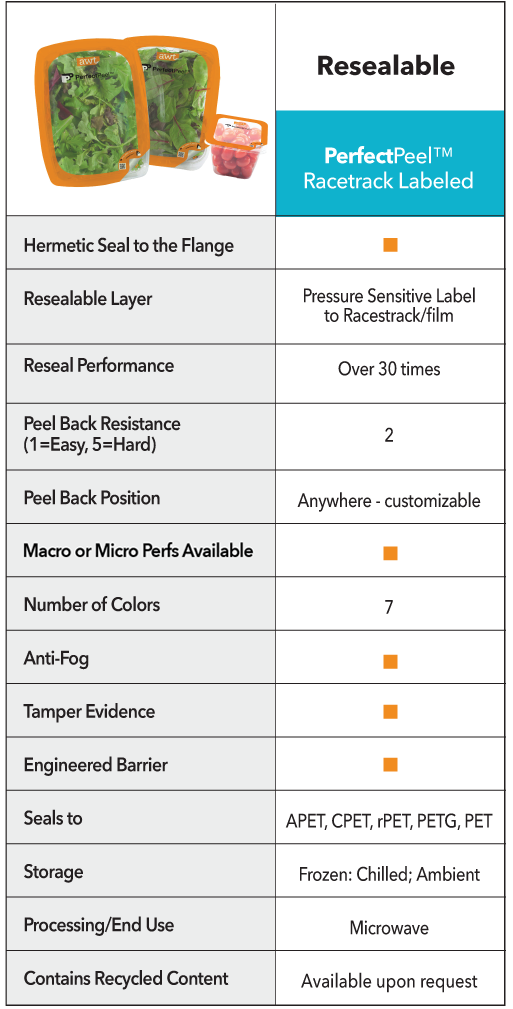

PerfectPeel™ Racetrack Labeled is premium, multi-layer lidding film designed for multiple-use packaging of 30+ open/closes in normal ambient conditions. It offers excellent optical clarity and reliable sealing—ideal for the demands of modern food and consumer packaging.

View our full line of lidding films:

FDA Conditions B-G & Safe Quality Food (SQF) Certified

Enhance the End-User Experience

Sustainability Matters

Boost Operational Efficiency

Tailored to Your Needs

Technical Highlights

Our Client A recognized world leader in biochips and micro-fabrication of solid-state diagnostic devices. Their products comprise a range of acute-care

When it comes to clinical trials, the importance of precision and accuracy cannot be overstated. Every detail counts, and this extends into what may seem like the minutiae of trial management: the labeling of clinical trial materials.

If your sealing station is slowing things down, you’re not alone. High temperatures and long dwell times can create bottlenecks, waste energy, and add unnecessary wear to your equipment.

AWT Labels & Packaging

Headquarters

600 Hoover St NE #500

Minneapolis, MN 55413

Join our mailing list and stay up to date on our expertise!

AWT is the trusted partner for leading brands; delivering comprehensive, innovative, and sustainable labeling, packaging, and converting solutions with exceptional quality, expertise, and responsiveness. © 2025 All Rights Reserved AWT | Terms & Conditions of Sale | Privacy Policy